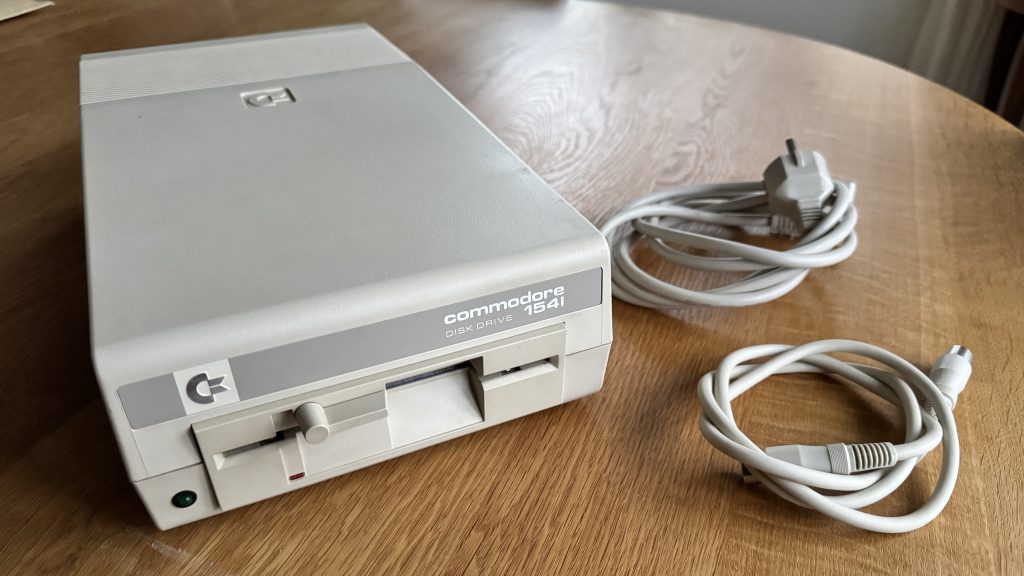

Commodore’s 1541-family of floppy drives went out of sales decades ago. The drives that remain in working condition have surpassed their life expectancy multiple times. In this post, I share my thoughts on what constitutes a proper test before listing a drive for sale.

A few notes about Commodore’s design

Before we discuss test procedures, I would like to say a few words about Commodore’s range of 5,25″ drives.

Commodore’s design is quite different from the drives-designs for other contemporary and later computers. Among the special features of the 1541 is that it contains a full feature computer with CPU, RAM, ROM, databus, serial interface and so forth. The 1541 resembles a VIC 20 and shares many of the same components. Other than the mainboard, the drive unit consisted of a power supply (internal or external) and a drive mechanism.

Commodore used a multitude of suppliers for drive mechanisms, mainboards and power supplies. Each model and variant has its own set of weaknesses. This is of course a consideration when designing your test procedure and interpreting the results.

Test equipment

When I get a new drive in, I never test it with any of the accompanying peripherals in the first go. If the drive doesn’t work, you want to isolate the number of potential root causes right from the start.

When testing 1541 and 1541C, I always use a know good power cable and a known good serial cable. I have so far not seen power cables fail, but serial cables do fail from time to time.

When testing 1541-II, I always use a modern replacement power supply.

Depending on the tests, you need to perform, you will need a blank disk and a factory formatted disk. I will revert to that later.

Test procedure

The test procedure that I describe here, is only relevant when the drive at least appears to boots up normally, i.e. that the spindle motor stops spinning when the drive or a connected computer boots up.

Additionally, I always start out by attempting to read the directory from a known working disk.

If the drive reads the directory, I move on to a more thorough test.

I prefer using Jani’s 1541 Diagnostic Cartridge, which among other things contains a Performance test.

The Performance test tests all basic functions of the drive, i.e. format, read, write, scratch. Further, it tests read and write operations on tracks 1 and 35.

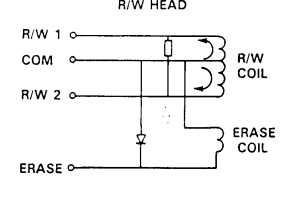

In particularly when working with drives based on Mitsumi or Newtronics mechanisms, it is necessary to test all functions because their R/W heads are vulnerable. And as the drives have separate R/W and erase coils, the R/W heads may fail partially, which makes it necessary to perform all types of tests.

Testing tracks 1 and 35 is important, as the drive may read track 18 (directory) but fail when reading one of the outer tracks.

In general, I consider a passed Performance test sufficient when dealing with Chinon, Mitsumi and Newtronics drives.

For Alps-drives, I recommend testing head alignment as well. For some reason, Alps-drives seem to be more prone to alignment issues, i.e. that the drive can’t read disks, unless they are formatted and written with the same drive.

When I perform an slignment, I use Jani’s alignment test and a “factory formatted” disk, as the factory standard is what you are supposed to be aligning to.

I use the Free Spirit alignment disk, but I consider the test equally valid if it i performed using the 1541 demo disk that came with the drive.

Burn-in testing?

One of the questions when testing retro equipment is, whether you should perform burn-in testing.

A burn-in test is essentially a repetitive test, which allows you to identify periodic failures, which otherwise may be difficult to see.

One type of failures that do occur on retro equipment is failures that only occur when components get hot. This could be loose connections.

I do not perform burn-in testing. There are multiple reasons for that.

First and foremost, I rarely get equipment sold as working back for repairts, which obviously implies that my current test procedure is sufficient.

Second, there is a safety-issue involved. With 1541 and 1541C, a recurring problem is that the tantalum capacitor C15 shorts and starts burning. I have seen it more than once. For that reason, I never leave a 1541 powered on and unattended. For that reason, I would never run longterm automatic tests.

Cables and power supplies

I test external power supplies (1541-II) using a Power Supply Tester from Keelog. The device measures the voltages from both the 5V and the 12V outputs of the power supply. Unlike a multimeter, the tester also measures current ripple.

Unlike on a C64 where you only need to worry about overvoltage on the 5V DC outputs, you need to check both the 5V DC and 12V DC outputs on the 1541-II power supply.

I do not test cables unless they are visibly damaged, have been modified or are homemade.

Leave a Reply