Commodore’s datasette is a robust little machine, and many of them still keep spinning. Furthermore, many of the most frequent problems can be fixed easily. This post contains my datasette repair notes, and will be updated regularly.

Some numbers

I have bought several lots of defect datasettes and it has been surprisingly feasible, if we ignore the time I have spend on learning how to repair them.

Until now, my repair ratio for datasettes purchased as “not working” is 88% with an ROI (return on investment) of 230%.

Some of the no fixes were sold for spares, while others went into my spareparts storage and became valuable for later repairs.

Typically, 8 out of10 datasettes purchased as “not working” either turn out to work only need simple servicing, which may include cleaning the r/w head, replacing the drive belt or adjusting azimuth.

Preparation

Testing and repairing aren’t always discrete activities when working on datasettes. The items below are the tools I prefer to have available whwen working o As a minimum, I suggest having the following items available for :

- A known working tape

- A known working C64 with a clean tape port edge connector

- A small screw driver, head sice around 2mm

- Isopropylachohol

- Cotton swaps

- Soldering iron

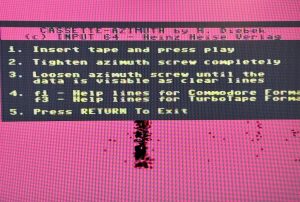

- A cartridge with Azimuth Head Alignment software

I also find it handy to have my component tester and chip tester available. I use the Backbit Chiptester and a cheap component tester from AliExpress.

Symptom: Tape doesn’t load

You test the datasette with a known working tape, but it doesn’t load, no sound is heard from the speaker and no “found” message comes up.

The most common reason for this problem is that the head azimuth setting it wrong. Adjusting azimuth without the necessary software is not easy, but it can be done. I do however recommend using the proper software.

In som cases, tightening the adjustment screw (rotate clockwise) may help out, but it is a bit like navigating a car in the blind.

If the tape is recorded with ABC turbo, and provided you are able to load the turbo loader itself, you may be able to adjust by looking at the rolling strips at the beginning of the load sequence.

Symptom: No signal

You test the datasette with a known working tape, but it doesn’t load, no sound is heard from the speaker and no “found” message comes up. You load Azimuth Head Alignment only to realize that there is no signal at all.

First and foremost, tou should try wiggling the tapedeck connector a bit. You should also do a physical inspection to ensure that all the pins in the connector are intact.

Second, check that the wires from the R/W head still are connected to the PCB. This exact part of the design is fragile, as the wires are soldered directly on to the PCB while the the R/W head assembly is a moving part. Eventually, the solder joints may get damaged.

If the connector and wires are intact, you need to remove the PCB and check the components. The 1530 service manual lists six different PCB versions. With the exception of assembly #320009 and #320109, all of them (#320275, #CMR-001-0, #NP-090 and #017-5001-0) are equipped with a 74LS14 which is likely to fail and cause the problem.

For #320009 and #320109, I have seen the same problem being caused by a failing transistor. Essentially, you should check all of them.

Symptom: Dots all over the place / far right

You test the datasette with a known working tape, but it doesn’t load. You load Azimuth Head Alignment and see a signal, but you see the black signal dots all over the place, or they form patterns to the far right of the picture.

In these cases, the first thing to try is to clean the r/w head with isopropyl alcohol on a cotton swab. Keep cleaning until you can’t get any more brown stuff of the r/w head.

Symptom: Hatch won’t open

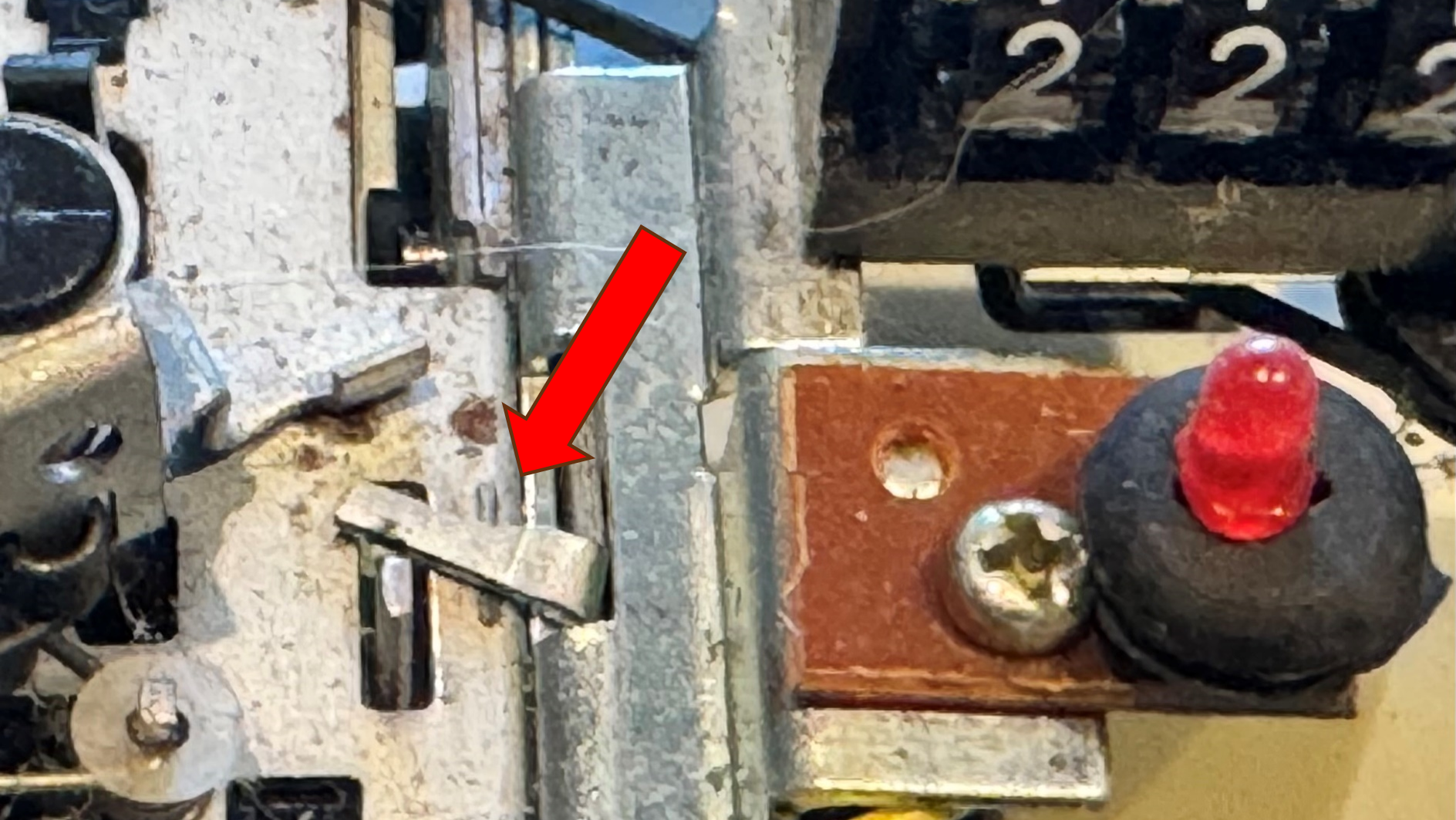

You press Eject, the hatch opens but only a few millimeters and it doesn’t stay up.

The issue is cause by a small metal arm (see red arrow) that has been bent. When the eject button is pressed, the hook under the metal arm is supposed to push the arm upwards. The arm is connected to the door release mechanism. But when the arm isn’t at a 90 degree angle to the hook that pushes it, it won’t move far enough and the door won’t open. To fix this, you simply bend the arm back so that it touches the hook when the eject button isn’t pressed.

Symptom: The datasette is noisy or eats tape

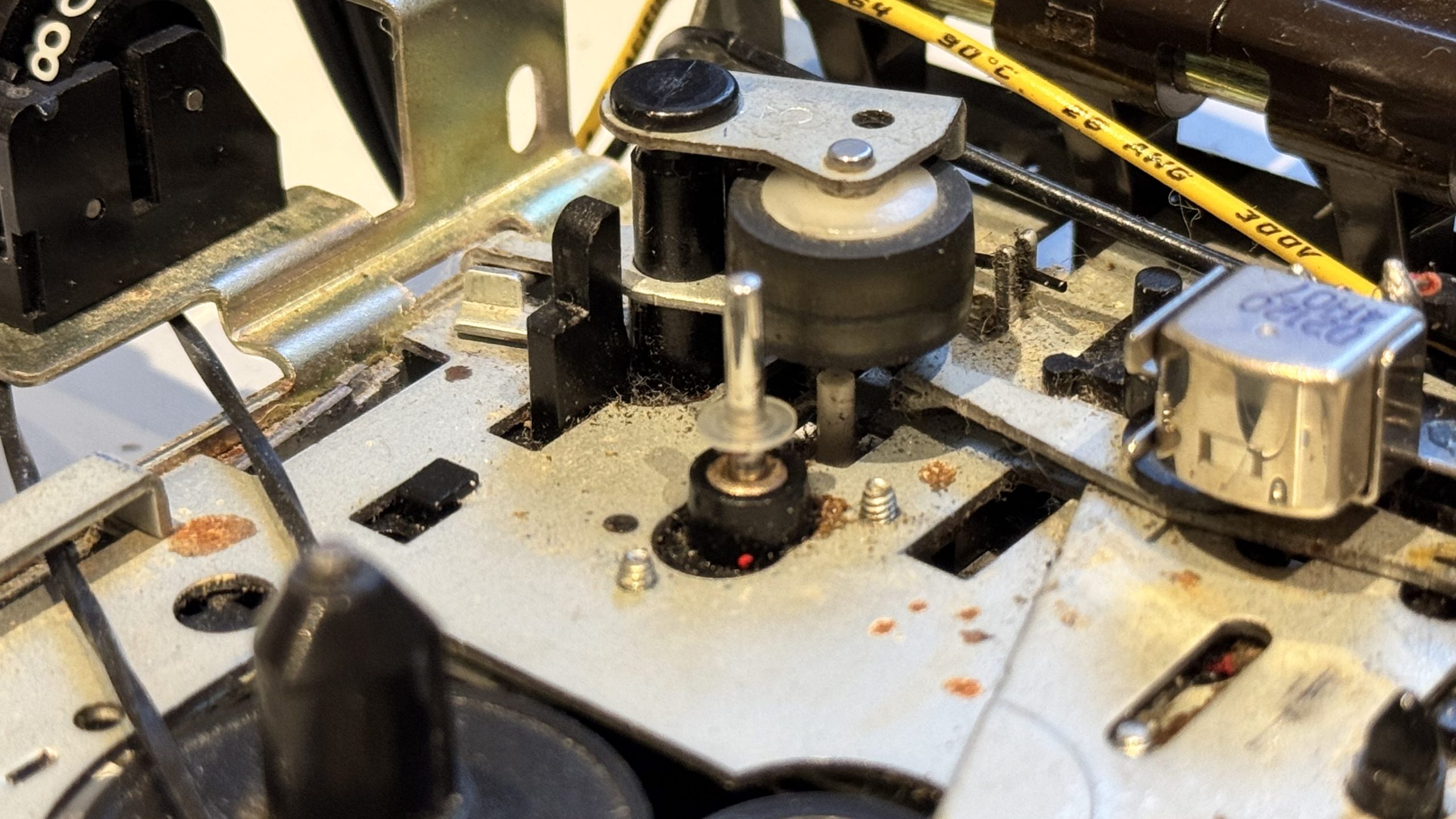

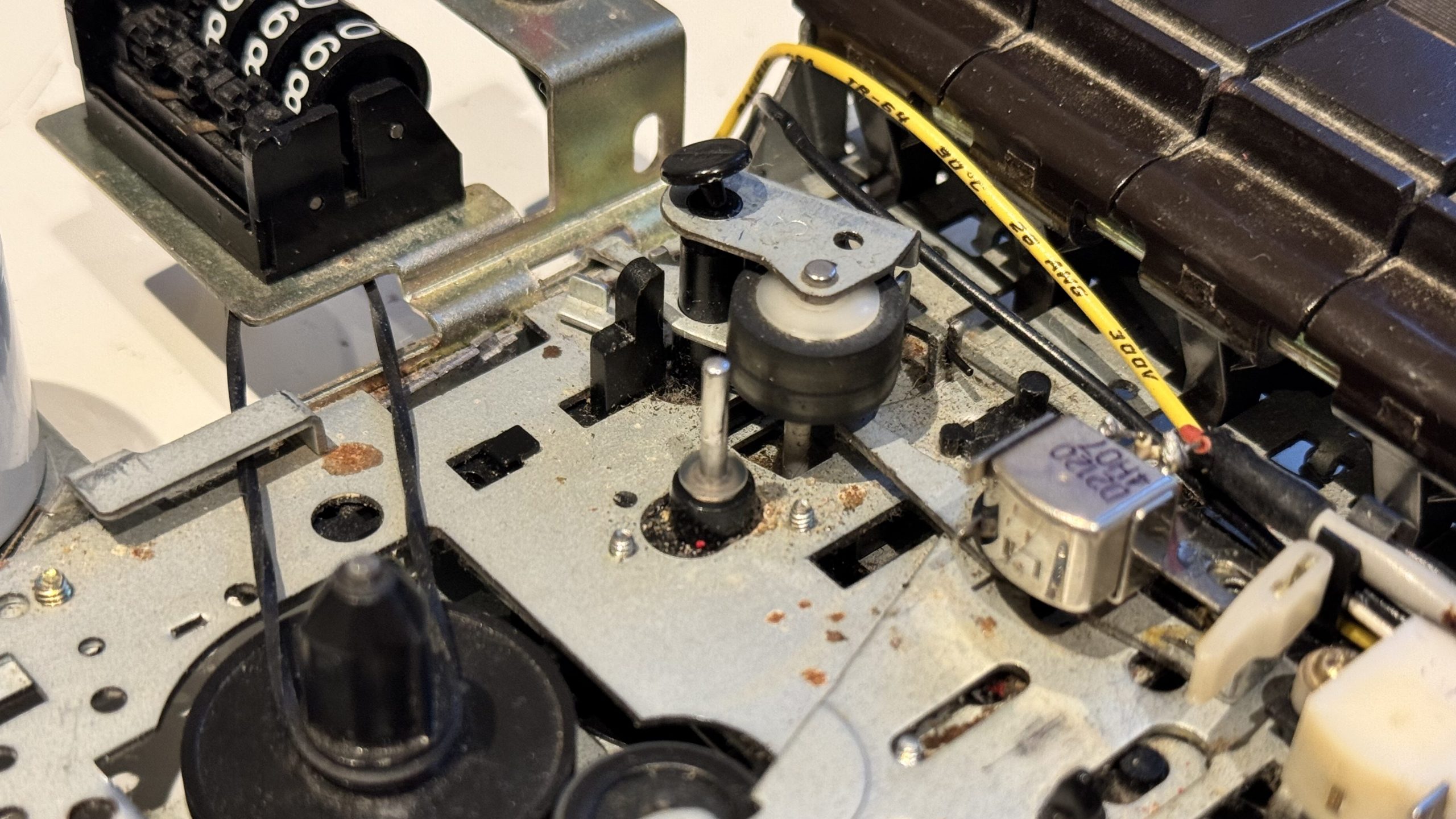

When the datasette is supplied with power, you can hear a scaping noise as the big drive wheel starts rotating even when no tape is inserted and no buttons are pressed.

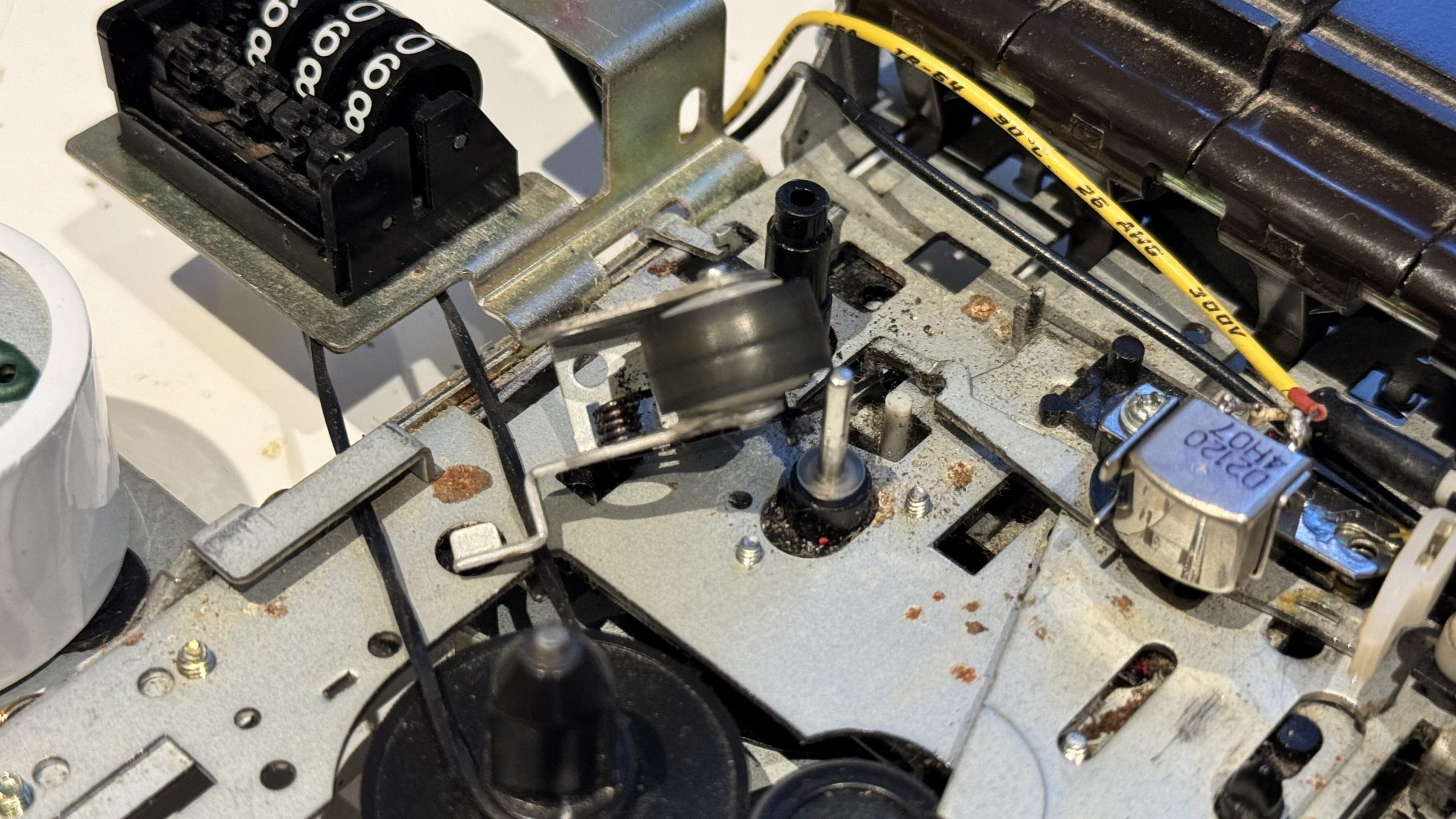

Now, noise may come from everywhere inside a mechanical device, but I have found that a good place to look is towards the securing disc on the capstan. In the picture below, the securing disc is moved out of position. Under normal circumstances, it is pressed all the way down to the mount, meaning that it holds the large drive wheel on the back of the tape mechanism in place. But it can somehow move out of position as seen on the picture, whereby the drive wheel drops to the bottom of the case and starts making noise. Most of the time, you just need to press the drive wheel upwards while pushing the securing ring downwards.

Symptom: The datasette eats tape

The other symptom is that the datasette “eats” tape. When you eject a tape, it will be hanging out of the cassette and may be squeezed behind the pinch roller.

There are multiple things to check when a datasette eats tape.

If the take-up reel (right spindle) is rotating, the most likely reason is that the pinch roller either is sticky or dirty. You may be able to solve it by cleaning the pinch roller with isopropyl alcohol, although the best solution may be to replace it.

To replace it, just remove the black plastic nail that holds the pinch roller assembly:

Next, remove the entire pinch roller assembly:

The next part depends on what spares you have available. If you have a working pinch roller assembly, the simplest solution is to replace the entire assembly. If you only have the pinch roller itself, you needs to bend the metal casing open, replace the roller and bend it back again.

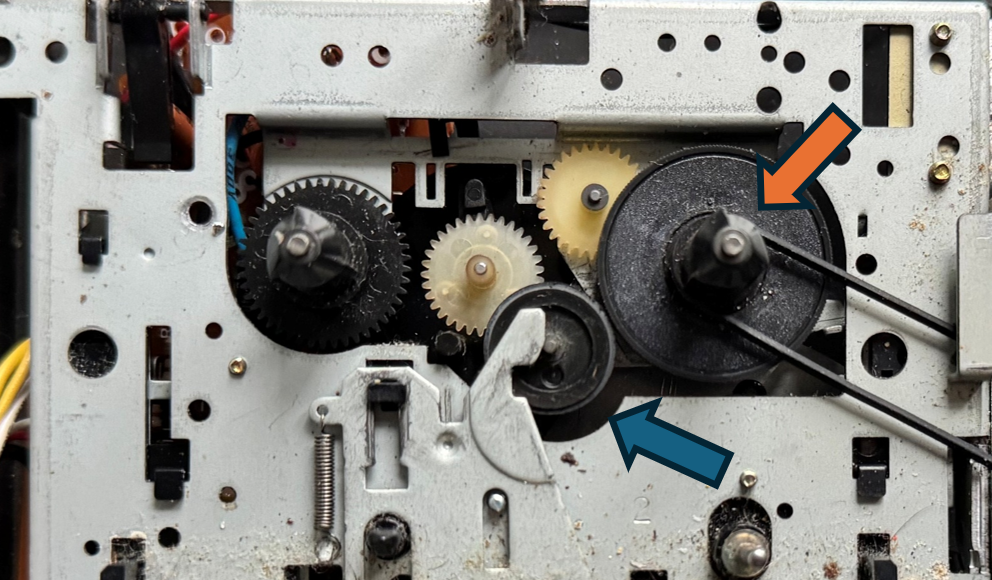

If the take-up reel (right spindle – orange arrow) isn’t rotating, the most likely reason is that the so-called idler wheel (blue arrow) has lost its grip. In that case, you will need to replace it.

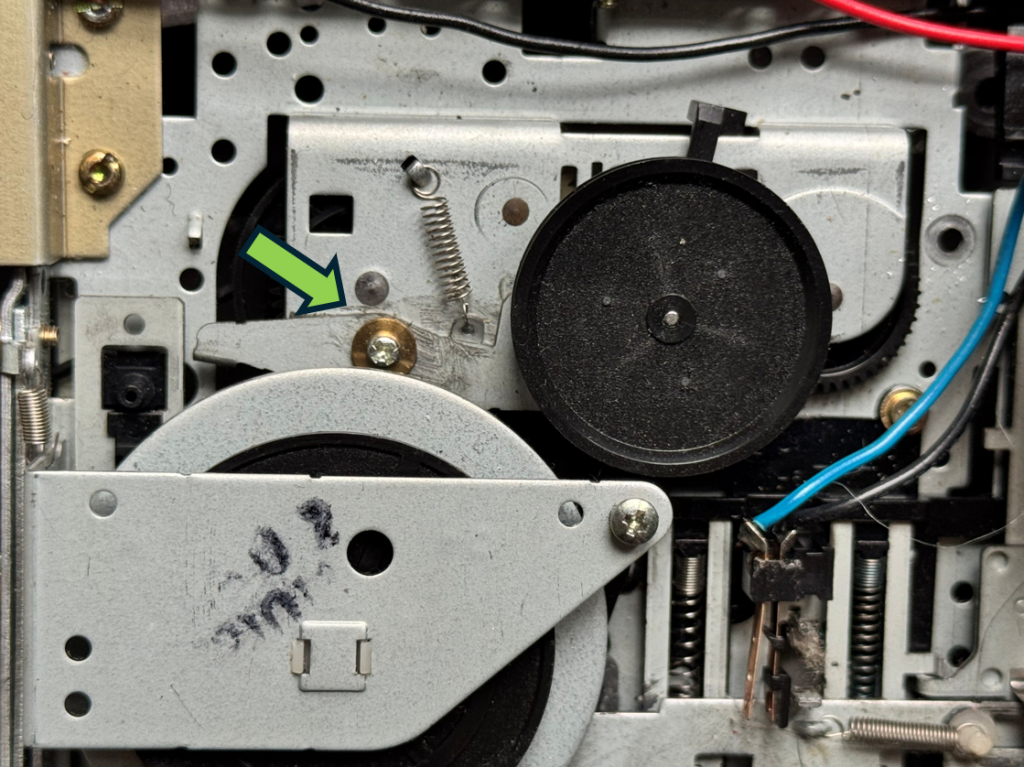

To replace the idler wheel, lift the small securing disc that keeps it in place. Then, flip the datasette over and remove the small screw (green arrow), thereby allowing the arm that holds the idler wheel to move freely. With the securing disc off, the wheel should fall of automatically and you can replace it. This requires a steady hand and a good pair of tweezers.

Symptom: Twisted signal bands in Azimuth

You insert the tape, load up Azimuth head alignment and adjust the datasette’s r/w head until you have two nice, straight, vertical signal lines on the screen. And then all of a sudden, the signal lines become skewed, start twisting and may even change place. You may hear a crackling sound from the datasette.

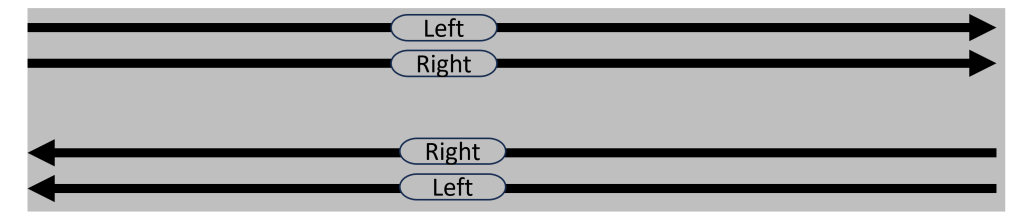

This happens because the tape is pulled out of position by the pinch roller. The picture illustrates the position of the magnetic tracks on the tape. Under normal circumstances, the r/w head is aligned with the tracks, but if the tape is being pulled out of position, for example by being squeezed and folded between the capstan and the pinch roller, the magnetic tracks won’t line up with the r/w head.

The few times I have seen this, the fix was to clean the pinch roller with isopropyl alcohol. It usually takes some scrubbing.

Leave a Reply